Our Good Manufacturing Practice (GMP) certified facility is located in Bandar Teknologi Kajang, Selangor (about 30 minutes drive from Kuala Lumpur) and have been in operation since 2007. The facility is over 4,000 sq ft and it is an expansion of another sister GMP facility which has been in the herbal manufacturing industry since 2003.

Reishilab GMP facility is equipped with the latest packing equipments ranging from 3-side-seal packing, pillow pack, capsuling, tableting, double pack tea-bag (tag & string without staple), blister packing, oven-drying, mixing, sieving, ink-jet printing etc.

The factory’s clean room production area is fully integrated with a centralized air-conditioned system (with pressure differentiation) while the entire factory’s floor area is coated with approved Epoxy material. We are also accredited with the Halal certification from the Department of Islamic Development of Malaysia (JAKIM).

GMP Facility

Good Manufacturing Practice (GMP) certified by Ministry of Health to manufacture products in capsule, sachet and tea-bag forms. The facility conforms to the strict regulations under the Sales of Drugs Act 1952 (Revised 1989) and The Control of Drugs and Cosmetics Regulations 1984 of Malaysia.

Clean Room

The facility’s flooring is coated with approved epoxy material for all clean room, grey and black areas. Clean room production area is ventilated by centralized air-conditioned system (with pressure differentiation) to ensure there is no cross contamination of raw materials during production.

Oven Drying

Low temperature oven drying facilities that maximize moisture extraction while ensuring raw material’s active substance are not compromised.

Blending, Mixing & Sieving

Blending and sieving facilities that ensures raw materials blending are evenly mixed prior to encapsulating or tableting.

Capsule Filling

Capsule Filling facility for various sizes of capsules (gelatin or vegetable). Capsule sizes include size 0, size 1 and size 2.

Blister Packing

Blister pack facility for tablets or capsules to achieve better product hygiene and better packaging appearance.

Sachet Packing

(3-side seal & pillow pack)

Packing of powder products into 3-side seal or pillow packs sachets using either aluminum foil, OPP + PE, laminated film OPP/CPP, Paper + PE or other special heat sealable film.

Double Layer Tea Bag Packing

Tea bag packing (without stapler) with string & tag packed together with outer aluminum or OPP bag to ensure cleanliness and freshness of tea leaves.

Disintegrating Test

Disintegrating test instrument to ensure all products adheres to the set parameters for disintegrating time and temperature during production.

Quality Assurance

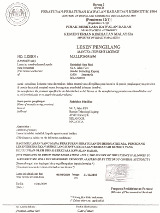

GMP Manufacturing License

GMP Manufacturer license issued by the Ministry of Health Malaysia that verifies the facility conforms to the strict regulations under the Sales of Drugs Act 1952 (Revised 1989) and The Control of Drugs and Cosmetics Regulations 1984 of Malaysia.

GMP Manufacturer license issued by the Ministry of Health Malaysia that verifies the facility conforms to the strict regulations under the Sales of Drugs Act 1952 (Revised 1989) and The Control of Drugs and Cosmetics Regulations 1984 of Malaysia.

GMP regulations aims to ensure that only products which meet the required standards of quality, efficacy and safety are registered and allowed to be manufactured, imported, supplied or sold. GMP regulations require a quality approach to manufacturing, enabling companies to minimize or eliminate instances of contamination, mix-ups, and errors.

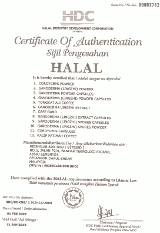

Halal Certification

Halal certification of our products are from the Department of Islamic Development of Malaysia (JAKIM). Halal refers to products that are allowed and permissible for consumption with relation to Syariah law as long as they are safe and not harmful.

Halal certification of our products are from the Department of Islamic Development of Malaysia (JAKIM). Halal refers to products that are allowed and permissible for consumption with relation to Syariah law as long as they are safe and not harmful.

These guidelines for the slaughtering of animals and the preparation and handling of Halal food will have to be observed at all establishments involved in the processing of Halal food. It will also serve as a basic for ascertaining the Halal status of the establishments by the relevant authority in Malaysia. These guidelines will apply to all foreign establishments intending to export their products to Malaysia and shall be used together with existing guidelines on Good Manufacturing Practices and hygienic sanitary requirements.

Food Irradiation

Food Irradiation is a technology to preserve and improve food safety. It is the process of exposing food to doses of ionizing radiation for a specific time to destroy micro-organisms, bacteria, viruses or insects that might be present in the food.

Food Irradiation is a technology to preserve and improve food safety. It is the process of exposing food to doses of ionizing radiation for a specific time to destroy micro-organisms, bacteria, viruses or insects that might be present in the food.